Risk Management Benefits of an Effective RBI Program – Driving Out the Snakes & Finding the Needles

By Greg Alvarado

Owner operators often ask about the benefits of RBI implementation. Our first response is effective risk management. This includes the ability to find the “snakes in the grass” or the areas of vulnerability that some may be blind to or simply unaware of.

At the 2017 API Inspection Summit, John Reynolds and Chad Patschke shared, from a high level, trends they had seen while conducting audits or gap assessments after numerous studies had been performed at refineries and petrochemical facilities across the US and Canada. One area for improvement was more attention to analysis of the vast mountains of data that were accumulating from inspections and related activities such as CCD and DMR work. A related challenge they also shared in this situation is that the data pointing to potential “bad actor” equipment resides in a very small percentage of the data “mountain”, or like looking for needles in haystacks.

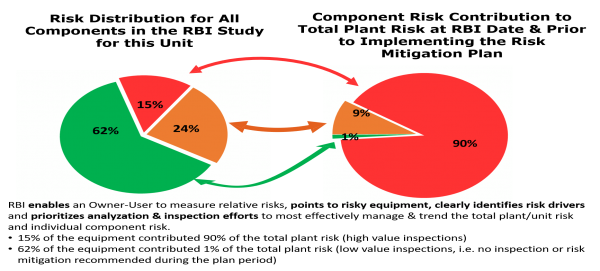

This is where quantitative RBI can really prove its value. Through risk analysis of pressure vessels and piping, done effectively, many the “needles” can be identified. Just like Pareto says, 80%-90% of risk is contributed by 10% to 20% of the equipment. As long as the equipment is included in the study, and the study is done effectively and efficiently (remember if we focus on efficiently first and make effectiveness take a back-seat, we may just be doing the wrong things faster), RBI will point us to the “bad actor” equipment and often operating and other practices that lead to bad things happening, i.e. by clearly pointing out the risk drivers!